A Detailed Overview On Acrylamide Tertiary Butyl Sulfonic Acid

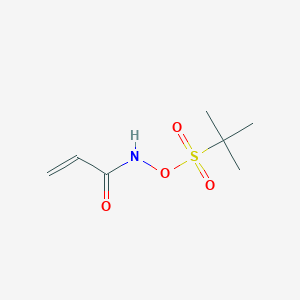

Acrylamide tertiary-butyl sulfonic acid is a special sulfonic acid acrylic monomer that is highly reactive. It is also known as AMPS (Acrylamide 2-methyl-1-propanesulfonic acid). This chemical is available as a powder, pellet or 50% aqueous solution as sodium salt

Properties Of ATBS

ATBS is a versatile substance that is hydrolytic is nature and possesses properties such as thermal stability, hydrophilicity, polarity and reactivity. It can be easily copolymerized with other chemicals like acrylonitrile, acrylic acid, acrylic esters and acrylamides as it is highly polymerizable. The aqueous solution of ATBS is acidic and soluble in Dimethyl, partly soluble in methanol and insoluble in acetone.

How Is ATBS Manufactured

ATBS is produced through the ritter reaction of acrylonitrile with isobutylene in the presence of sulfuric acid and water. This mixture is heated to obtain 2-acrylamido-2-methyl propane sulfonic acid.

Uses Of ATBS

The main use of ATBS is in the oil recovery industry where it is used in its highest purity grade. Other uses of ATBS are in water treatment, acrylic fibre, oilfield, latex, adhesive, emulsion coatings, personal care, medical and construction applications.

Due to their exceptional thermal and hydrolytic stability, ATBS granules are used in oilfield applications where hostile environments demand high-performance products. In drilling operations, ATBS granules are also utilized as scale inhibitors, friction reducers, non-retarding fluid control agent and water-control.

ATBS is used in adhesives as it greatly improves their thermal-mechanical properties and adhesive strength.

Polymers containing 15214-89-8 are used in diapers, lotions and personal care products due to its water retention capacity, electrical conductivity, slipperiness and lubricity. Being super absorbent, they are also used in the agricultural sector as a water retention agent.

Polymers containing ATBS are known to improve dispersibility and lubricity. That is why, they are used as flow control auxiliaries in building materials

Polymers containing 2-Acrylamido 2-methylpropanessulfonic Acid improve the characteristics of hydrophilicity, dispersibility, lubricity and enhance the effectiveness of Detergents and Cleaners

Vinati Organics is the leading manufacturer of IBB and ATBS monomer in the world. We blend innovation with chemistry to deliver value-added products to our varied clientele. Since our inception in 1989, we have evolved from a single product manufacturer to an integrated business which offers a wide variety of products to some of the largest industrial and chemical companies in US, Europe and Asia.

Over the years, we have managed to build a strong foothold in more than 35 countries in the world due to our research capabilities and ability to develop new and green chemicals with high standards of purity. All our investments in R and D are aimed at modifying the utilization of catalysts, equipment, processes and operating parameters. Moreover, to make a sustainable difference, we invest in technologies that minimize the impact of global warming and enables us to develop green chemistry.

Our two state-of-the-art manufacturing facilities in Maharashtra are integrated with a B2B business model and equipped with the latest technologies and adhere to green practices that minimize harm on the environment.