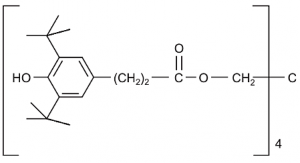

VEENOX® 1010 (HINDERED PHENOL ANTIOXIDANT)

General Information and Properties

CAS no: 6683-19-8

Molecular formula: C25H42O3

Molecular weight: 1178 g/mol

Physical Properties

| Parameter | Specification |

| Appearance | White, free flowing powder |

| Melting Range | 110 – 125°C |

| Specific Gravity | 0.95 to 0.99 gm/cc |

| Viscosity | @ 40°C 95 – 150 cSt |

| Flash Point | 297°C |

| Density (20 °C) | 1.15 g/ml |

| Bulk Density | 530 – 630 g/l |

Properties That Influence the Application and Performance

- Oxidation Inhibition

As a primary antioxidant, Veenox 1010 efficiently inhibits the oxidation process by scavenging free radicals, thereby preventing chain reactions that lead to material degradation.

- Thermal Stability

The chemical’s impressive thermal stability allows it to function effectively in high-temperature applications, protecting materials even under elevated processing conditions.

- Non-Discolouring

Veenox 1010’s non-discolouring nature ensures that the appearance and aesthetics of the end products remain unaffected, maintaining their visual appeal over time.

- Enhanced Shelf Life

With Veenox 1010, you can significantly extend the shelf life of your products, ensuring that they maintain their quality and efficacy for a longer duration.

- Dosage

Dosages ranging from 500 ppm to 1000 ppm of Veenox 1010 PW provide long-term thermal stability to the polymer. Higher dosages may be used depending on the substrate and the requirements of long-term thermal stability of the end application.

Applications of Veenox 1010

- Polymer And Plastic Industry

Veenox 1010 serves as a primary stabiliser for polymers and plastics like PVC, Masterbatch and Polyethylene, Polypropylene, Polystyrene, providing long-term protection against degradation caused by heat, light, and oxygen exposure. Its role in inhibiting chain scission and cross-linking reactions ensures the preservation of mechanical and physical properties, resulting in durable and high-quality materials.

- Rubber Manufacturing

In the rubber industry, Veenox 1010 contributes to the prevention of degradation, maintaining the elasticity and resilience of rubber-based products, even in challenging environments.

- Adhesives and Sealants

As an antioxidant in adhesives and sealants, Veenox 1010 enhances the stability and performances of these formulations, promoting reliable bonding and sealing properties.

- Coatings And Paints

Veenox 1010 is employed as an additive in coatings and paints to protect against oxidative degradation, ensuring that coated surfaces maintain their appearance and structural integrity over time.

- Lubricants And Oils

The chemical’s thermal stability makes it an ideal choice as an antioxidant for lubricants and oils, safeguarding machinery components and extending their service life.

- Other Important Applications

Beyond the mentioned industries, Veenox 1010 is employed in coatings, sealants, and various other applications, ensuring superior protection against degradation.

Packaging & Shipping Information

- The product is available in both PW (Powder) and GR (Granule) form.

- Packing: 25kg/Bag, 500kg/Pallet, 10MT/20’FCL.

- Our product is EU REACH certified.

As one of the leading manufacturers of organic chemical products in India, Vinati Organics takes pride in offering world-class quality antioxidant 1010. As a prominent manufacturer of Veenox 1010 and other cutting-edge antioxidants, vinati organics continues to make significant contributions to diverse industries worldwide.

Vinati Organics have established the effectiveness and reliability of all the chemical products through extensive research and rigorous testing, primarily to keep the process and final products organic. With an unwavering commitment to excellence and a global reputation for top-quality and highly effective products, Vinati Organics is a pioneer in manufacturing innovative chemical compounds.

Leveraging expertise in the domain, we deliver solutions that cater to your specific industrial needs. Abiding by stringent industrial standards, with Vinati Organics as your partner, thrive into the realm of excellence.

Note: For more detailed technical specifications, product data sheets, or any specific queries, please contact our customer support team.