Phenolic primary antioxidant for processing and long-term thermal stabilization

Overview

Veenox 1076, a sterically hindered phenolic antioxidant, is a highly efficient, non-discolouring stabilizer for organic substrates such as plastics, synthetic fibres, elastomers and adhesives. It protects these substrates against thermal and oxidative degradation. Veenox 1076 PW is odourless, stable to light and has excellent colour retention. It has good compatibility with most substrates, low volatility and high resistance to extraction.

CAS no: 2082-79-3

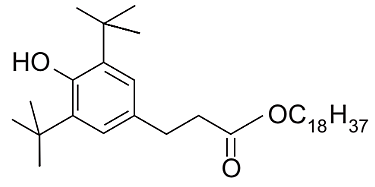

Chemical name: Octadecyl-3-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate

Molecular formula: C25H42O3

Molecular weight: 531 g/mol

Physical Properties

| Parameter | Specification |

| Appearance | White, free flowing powder |

| Melting Range | 50 – 55°C |

| Flash Point | 273°C |

| Density (20 °C) | 1.02 g/ml |

| Bulk Density | 360 – 400 g/l |

Solubility @ 20°C

| Solvent | g/100 g solution |

| Chloroform | 57 |

| Benzene | 57 |

| Cyclohexane | 40 |

| Toulene | 50 |

| n-Hexane | 32 |

The exceptional properties of Veenox 1076 play a crucial role in determining its application versatility and overall performance in various industries. Understanding these fundamental properties is essential for harnessing the full potential of this remarkable hindered phenolic antioxidant:

Veenox 1076 finds versatile applications across a wide range of industries, contributing to the enhancement of materials quality and longevity:

Polyolefins

Veenox 1076 provides long-term thermal stability in the polyolefin industry, making it an indispensable additive in polyethylene, polypropylene, and polybutene-1.

Engineering Plastics

Veenox 1076 plays a vital role in stabilising engineering plastics, such as styrene homo and copolymers, along with plastics like PVC, Masterbatch and Polyethylene, Polypropylene, Polystyrene ensuring their resilience and performance in demanding applications.

Polyurethanes and Elastomers

The application of Veenox 1076 extends to polyurethanes and elastomers, protecting against oxidation-induced degradation and maintaining the materials’ mechanical properties.

Adhesives

As an antioxidant in adhesives, Veenox 1076 enhances stability and extends the lifespan of adhesive formulations, ensuring reliable bonding and performance.

Adhesives and Sealants:

As an antioxidant in adhesives and sealants, Veenox 1098 enhances stability and performance, promoting reliable bonding and sealing properties.

Rubber Industry

Veenox 1010 and Veenox 1076 go into Rubber applications. Veenox 1076 is preferred in HIPS & ABS due to its rubber content.

As an established, prominent chemical manufacturer, Vinati Organics is known for its commitment to excellence and innovation. With a track record of delivering top-quality antioxidants, including Veenox 1076 (CAS no.2082-79-3), Vinati Organics has earned the trust and recognition of various industries worldwide. Its dedication to providing exceptional chemical solutions makes Vinati Organics a preferred partner for enhancing the performance and durability of diverse materials.

Explore the potential of Veenox 1076 and witness the transformative impact it brings to your materials’ quality. Trust in the expertise of Vinati Organics and embark on a journey of excellence, reliability and cutting-edge chemical solutions.

Note: For more detailed technical specifications, product data sheets, or any specific queries, please contact our customer support team.