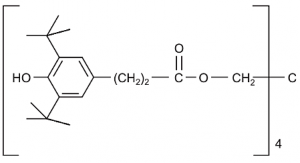

Phenolic primary antioxidant for processing and long term thermal stabilization

Veenox 1010 PW is a sterically hindered phenolic antioxidant. It is a highly effective, non-discolouring stabilizer for organic substrates such as plastics, synthetic fibres, elastomers and adhesives. It protects these substrates against thermal and oxidative degradation.

CAS no: 6683-19-8

Molecular formula: C25H42O3

Molecular weight: 1178 g/mol

Physical Properties

| Parameter | Specification |

| Appearance | White, free flowing powder |

| Melting Range | 110 – 125°C |

| Specific Gravity | 0.95 to 0.99 gm/cc |

| Viscosity | @ 40°C 95 – 150 cSt |

| Flash Point | 297°C |

| Density (20 °C) | 1.15 g/ml |

| Bulk Density | 530 – 630 g/l |

CAS 6683-19-8 refers to the chemical identification number for Veenox Antioxidant 1010, a sterically hindered phenolic antioxidant widely used for polymer stabilization. This antioxidant, identified under CAS 6683-19-8, offers exceptional oxidative stability, making it suitable for plastics, elastomers, adhesives, and coatings. Its high molecular weight ensures low volatility and excellent processing stability, even at elevated temperatures. At Vinati Organics, we ensure that our Veenox Antioxidant 1010 (CAS 6683-19-8) meets stringent international quality standards for consistent performance in demanding applications

As one of the leading manufacturers of organic chemical products in India, Vinati Organics takes pride in offering world-class quality antioxidant 1010. As a prominent manufacturer of Veenox 1010 and other cutting-edge antioxidants, vinati organics continues to make significant contributions to diverse industries worldwide.

Vinati Organics have established the effectiveness and reliability of all the chemical products through extensive research and rigorous testing, primarily to keep the process and final products organic. With an unwavering commitment to excellence and a global reputation for top-quality and highly effective products, Vinati Organics is a pioneer in manufacturing innovative chemical compounds.

Leveraging expertise in the domain, we deliver solutions that cater to your specific industrial needs. Abiding by stringent industrial standards, with Vinati Organics as your partner, thrive into the realm of excellence.

Note: For more detailed technical specifications, product data sheets, or any specific queries, please contact our customer support team.

What physical properties does Veenox 1010 (CAS 6683-19-8) have?

Veenox 1010 is a white, free-flowing powder with a melting range of 110–125 °C.

It has a molecular formula of C₂₅H₄₂O₃ (for the active portion as per Vinati) and a molecular weight of around 1178 g/mol. Its flash point is very high (297 °C), which contributes to its thermal stability in high-temperature applications

How much Veenox 1010 should be used (dosage) in formulations?

The typical dosage of Veenox 1010 (CAS 6683‑19‑8) ranges from 500 to 1,000 ppm, depending on the polymer and processing conditions. Using the correct amount ensures optimal antioxidant protection without affecting physical properties. Higher dosages may be required for long-term stability in demanding applications.

Is Veenox 1010 (CAS 6683-19-8) compatible with other stabilizers?

Yes it can be used in combination with secondary antioxidants such as phosphites / thioethers to create a synergistic effect. Because of its low volatility and high molecular weight, Veenox 1010 helps improve long-term performance when paired with other stabilizers. Its non-discoloring nature means it doesn’t negatively affect the aesthetic of the final product when used with other additives.

How does Veenox 1010 improve thermal stability in plastics?

Veenox 1010 (CAS 6683‑19‑8) acts as a sterically hindered phenolic antioxidant, neutralizing free radicals generated during high-temperature processing. This prevents polymer chain degradation, discoloration, and loss of mechanical properties. It is particularly effective in high-heat applications like extrusion and injection molding.

Can Veenox 1010 (6683‑19‑8) be used in food-contact polymers?

Yes, Veenox 1010 (CAS 6683‑19‑8) can be used in certain food-contact plastics such as polyethylene films and packaging materials. Its high molecular weight and low volatility minimize migration into food. Regulatory compliance should always be verified before use in food-contact applications.

Is VEENOX 1010 compatible with other antioxidants?

Yes. VEENOX 1010 can be blended with phosphite antioxidants, thioesters, UV absorbers, and HALS stabilizers to create synergistic stabilization packages for polymers.